Wood has been used as a construction material since very early in recorded history. Like limestone, it has the ability to blend into the surrounding landscape while providing functional uses such as mulching, edging, benches and walkways. Wooden timbers can be stacked to form short walls which create landscape areas and transition grades throughout open spaces.

In constructing tall timber walls the designer must consider the type of timber, foundation, backfill and connections.

Timber

Certain types of wood are stronger than others. Commercially available landscaping timbers and railroad ties are generally of a more dense type of wood that is stronger than most. Timbers are impregnated with a preservative to resist the effects of moisture and insects. Creosote, a common preservative, is the black sticky covering on railroad ties and telephone poles. Landscaping timbers use other preservatives that are more user and environmentally friendly. If the wood selected for a timber wall is not treated, preservatives that can be applied by brush or spray are available.

Landscaping timbers are available in only two or three sizes. A size must be selected to correspond to the height of the wall. Taller walls use larger, heavier railroad-sized timbers.

Foundation

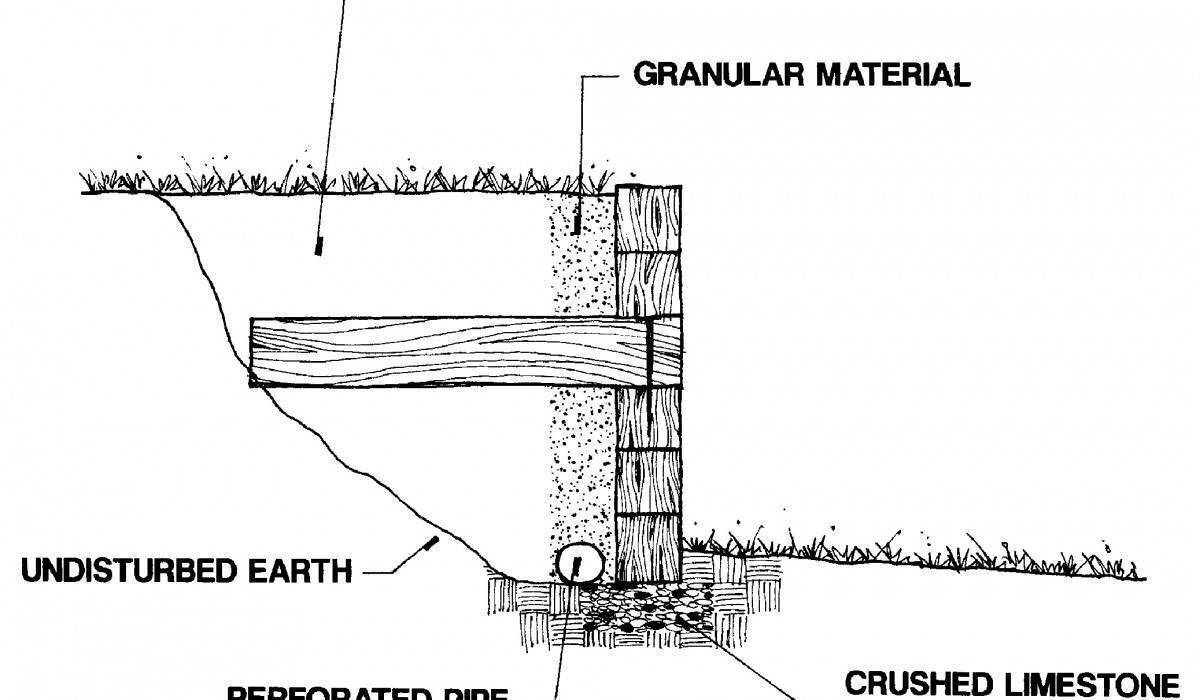

Prior to placing the first layer of timbers, remove all topsoil and soft subgrade material. A 6-inch layer of crushed limestone is placed and compacted for the timber wall’s foundation. The width of this foundation must exceed the width of the timbers by at least 6 inches. The top of the crushed limestone should be 2 to 4 inches below the finished grade of the face of the wall.

Backfill

Since the increase of moisture in soil behind the wall is the cause of most wall failures, a perforated drain pipe must be placed on the foundation at the back of the wall. Large sized crushed limestone is placed around the pipe to act as a filter. Two different backfill materials are often used. Large sized crushed limestone is placed against the wall creating a wick to draw accumulated moisture down to the perforated pipe. Low swell potential material (smaller sized crushed limestone or sandy clay material) is placed between the wick and the undisturbed earth. All material when placed is compacted in layers to reduce settlement potential.

Connection

Shorter landscaping timber walls are often connected with spikes or long nails. Driving a nail through preservative treated wood is difficult, so pre-drilling is advised. Taller walls use spikes and bolts. As the height of the wall increases, the need for an anchoring system also increases. The diagram above shows a typical timber wall cross section. The anchoring system is one of the timbers turned at a right angle to the wall and buried in the backfill. This timber is nailed or bolted to the timber beneath. Other methods of anchoring include geogrids and cables attached to blocks or timbers buried several feet behinds the wall. Crushed limestone is recommended for use as backfill material behind the timber walls.

Assistance

Most businesses who sell landscaping timbers have product literature available that is produced by the manufacturer of the landscaping timbers. Local contractors and landscaping firms will provide valuable location specific information.